Distilling 101, Distilling Hardware, Tools and Equipment

What Is A Vapor Management Still? (And How Do They Work?)

A vapor management still is 1 of 3 different methods for the control of reflux within a distillation column. These include vapor management (VM), liquid management (LM), and cooling management (CM).

Table of Contents

What is a vapor management still?

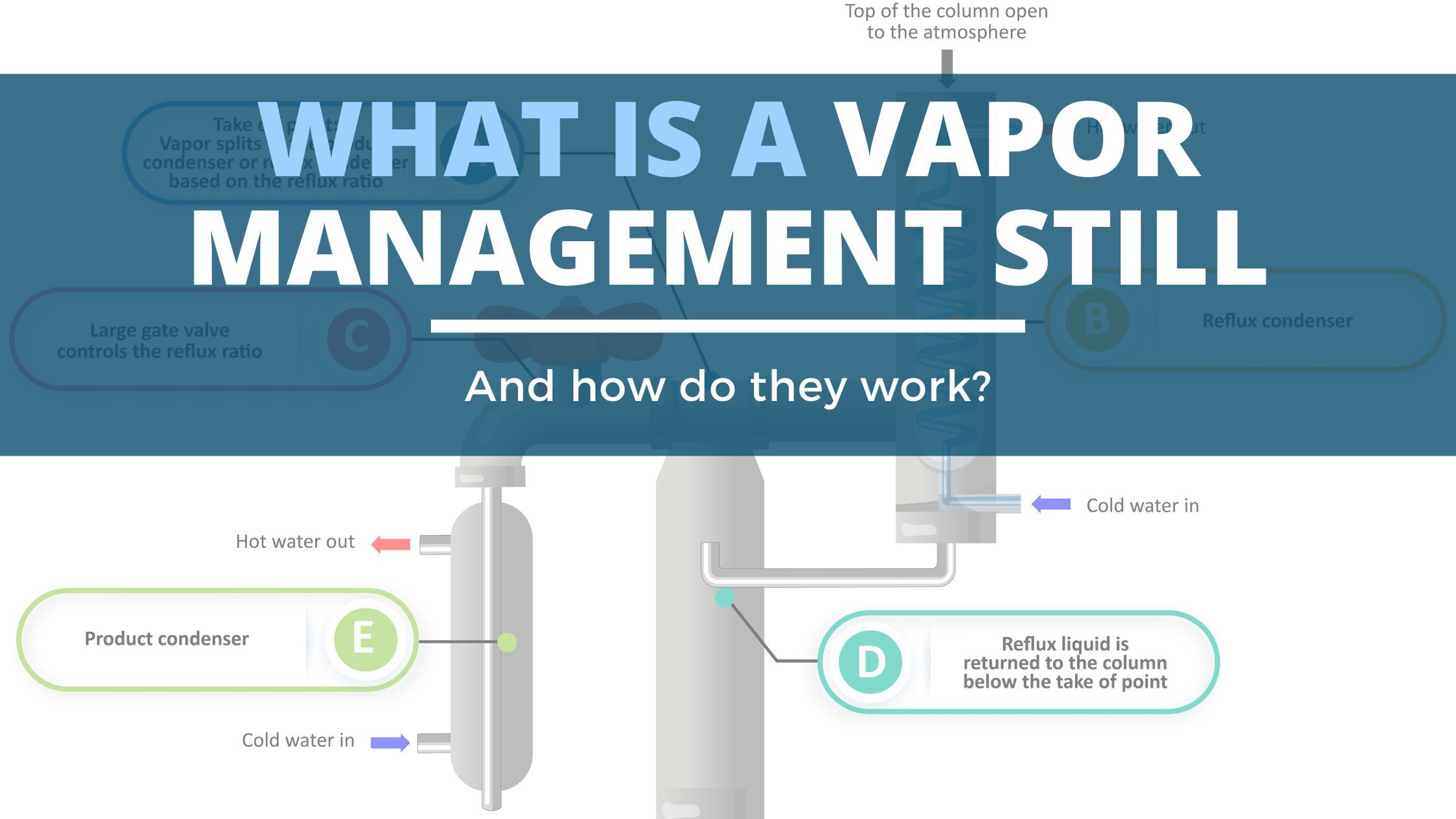

A vapor management still is a method of reflux control set by a gate valve or ball valve. Vapor management is almost the opposite of liquid management, which condenses everything and then splits the liquid. Vapor management splits the vapor into 2 streams and condenses each individually. Because the streams are split before reflux is generated, you receive approximately a 1:1 ratio of reflux regardless of the amount of vapor. The ratio of reflux remains the same and output will fall as the ratio of reflux is what you want to set and remain constant. The valve on a vapor management still sets the ratio of reflux, not the initial amount.

Components of a vapor management still

A vapor management still is comprised of several key parts including:

- A still column with a reflux condenser at the top.

- A tee piece below to branch to the product condenser.

- A gate valve or ball valve off the tee piece controls the flow of vapor.

How does a vapor management still work?

A vapor management still works by using a large gate valve to control the amount of vapor that goes into the reflux condenser and the end basin. With vapor management, vapor will rise up the column and split into 2 streams at the tee. The streams of vapor that continue toward the top are condensed by a reflux condenser and will then back down the column. If the gate valve is closed, the cycle continues reaching an equilibrium in which the alcohol components are separated within the column. Once the fractions of alcohol are separated, the gate valve can be opened slightly to allow a small quantity of vapor to pass through. This vapor then flows through the product condenser for final collection.

IMPORTANT: The top of the reflux condenser should ALWAYS be open to the atmosphere to ensure no pressure is in the still. Alcohol cannot escape out the top if there is enough flow of coolant through the condenser. If the top of the reflux condenser is sealed, an explosion may occur.

What is a vapor management still good for making?

A vapor management still is generally used for the production of large quantities of ethanol. With a vapor management still, you are unable to produce a small enough ratio of reflux that is suitable for flavored spirits. Because the valve settings remain constant, the ratio of reflux remains consistent. This is good for producing high-proof alcohol with minimal to no flavor, such as vodka and moonshine.

Advantages of a vapor management still

- A vapor management design allows for very fine adjustments to be made to control the flow of reflux within the still.

- A vapor management still is considered one of the easiest to operate as it requires less intervention.

- A vapor management system is constant and predictable. You can set your specific ratios to extract heads and it will stay.

- The ratio is simple and easy to change when you’re going through each process.

Disadvantages of a vapor management still

- With a vapor management still, it can be very difficult to discover the ratio of reflux.

- Vapor management limits the amount of reflux you can produce which is not suited for flavored spirits.

- Vapor management is less effective for extracting heads, resulting in a higher proportion of heads present in the final run.

- A vapor management still is considered neutral and does the trick but is not an outperforming option.

What to consider if building a vapor management still

There are dozens of different stills that are created for the purpose of distillation. Each still has its own advantages, disadvantages, and specialties. If you are thinking about building a vapor management still it is important to consider these factors:

- Do you want to produce high-proof alcohol with less flavor or do you want to produce intense flavors?

- Do you have proper ventilation around the still and above the reflux condenser to the outside atmosphere?

- What ratio of reflux are you hoping to achieve?

- Are you looking for clean extraction of heads?

- Are constant adjustments important to you?

NOTE: When building a still for the distillation of alcohol, it is important to always research your local laws before commencing.

Frequently asked questions

Q. What does VM stand for?

VM stands for Vapor Management.

Q. Is a vapor management still easy to use?

A vapor management still is considered one of the easiest stills to operate as it requires less intervention. To control a VM still you only need to operate the take-off valve. other stills, like the popular CM still. requires the operator to balance the flow of cooling water with the temperature of the cooling water AND the power into the boiler – a much more complicated operation.

Q. What ratio of reflux can you expect within a vapor management still?

You can expect to receive approximately a 1:1 ratio of reflux regardless of the amount of vapor.

Q. Is a vapor management still good for making flavored alcohol?

A vapor management still is unable to produce a small enough ratio of reflux suitable for flavored alcohols. Vapor management stills are good for making high-quality, unflavored spirits.