Distilling 101, Fermentation

The Ideal pH for Mashing And Fermentation (+ How To Adjust It!)

It’s important to know and control the pH all the way through the brewing process. From mashing, to ensure optimal starch conversion, through to fermentation, so our yeast propagate correctly and produce the desired flavor congeners.

But what pH are we trying to get to?

The best pH varies based on what you’re brewing, be that beer, wine, cider, whiskey or any other spirit. It also depends on the grains used and the type of yeast you’re using. Generally, a pH of 5.2 – 5.4 is good for mashing, and a pH of 4.8 – 5.2 should be maintained during fermentation.

In this article, we’re going to explain why this is, and what you can do to control the pH in your brewing process.

Table of Contents

What is pH?

The acronym pH stands for ‘potential of hydrogen‘ and essential is a measure of free hydrogen ions, which tells us how acidic or alkali a solution is.

The pH scale ranges from 1 to 14, with 1 being extremely acidic and 14 being very basic. A pH of 7 is neutral.

How Does pH Affect Mashing?

Mashing is the conversion of starch in grains like barley, corn, wheat etc into sugars that can be fermented by the yeast.

By controlling the pH down to between 5.2 and 5.4 we tend to see far better enzyme activity and a higher mash efficiency (the conversion from starch to sugar). It also aids in clarification, flavor stability, and inhibiting bacteria growth.

How Does pH Affect Fermentation?

PH levels affect the shape of proteins and and environment too acidic or too basic will effectively bend or break the yeast proteins – denaturing them.

Through evolution and natural selection, yeast these days have an ‘optimum pH’ where they are happiest and will perform the best.

This article cites research that finds yeast growth rates maximized between a pH of 5.0 and 5.5. Furthermore, this article cites how contamination from lactic acid bacteria can be minimised by ensuring the pH is below 5.5 as LAB is most prolific between 5.5 and 5.8.

We, therefore, suggest that maintaining a fermentation pH of between 4.8 and 5.2 will allow the fermentation to proceed at the correct rate and will inhibit microbial action that damages the end product. It will also allow to yeast to produce fewer unwanted flavor congeners and better flocculate at the end of the process.

How And When Do You Measure the pH?

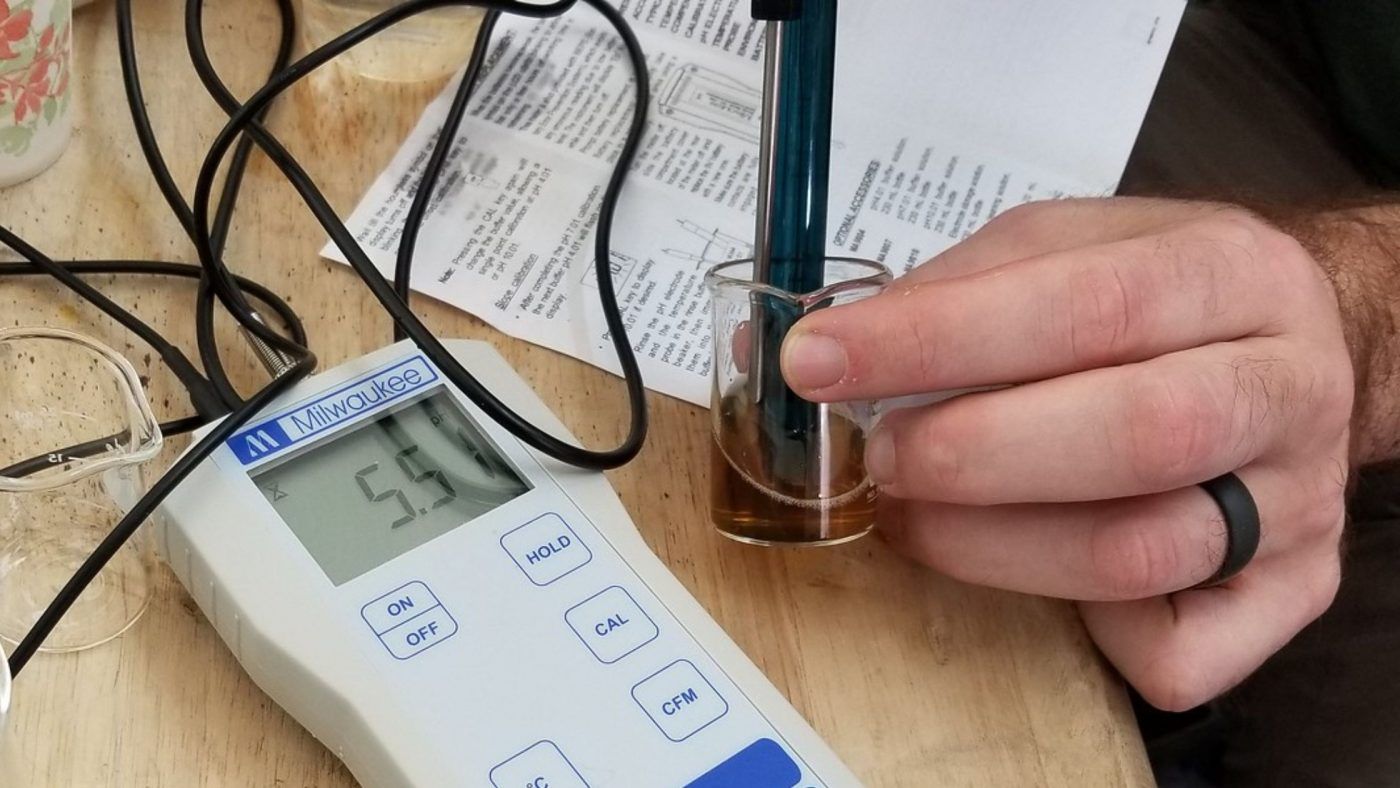

Measure the pH level by using either a digital pH meter or pH test strips. We recommend a cheap handheld digital meter for the convenience and accuracy.

Our recommendation: I have been using this mid-range digital pH meter from Milwaukee for over two years now after going through a number of cheaper no-brand ones that quickly stopped working or refused to stay calibrated. Milwaukee is a great trustworthy brand and I also found the cabled probes much safer and better to use than the ‘pen type’ meters that are more common.

- Ideal for anyone working on a low budget but still requiring fast and reliable measurements

When To Measure The pH?

- During the mashing process – Wait at least 5 minutes after doughing-in for the mash to settle and for conversion to start. Take a sample from as close to the midpoint of the mash as possible. I recommend using a glass and taking a very small amount of liquid so I can cool down faster, as pH readings are generally taken at room temperature (though your probe should correct for temperature).

- At the start of fermentation – Before pitching the yeast take another sample and check you are within the correct range.

- Every 2 or 3 days during fermentation. Continue to measure every two or three days to track the pH through fermentation. If you find that the pH level continues to drop, you can adjust the pH upwards to avoid a failed or stalled fermentation.

How to draw a sample:

Don’t put the pH meter into the fermenter as you risk contamination!

Samples should be drawn from a tap in the middle of the fermentation vessel. This is done to ensure that fermentation is not disturbed. More importantly, this is done to prevent oxygen from entering the fermentation vessel, as it will reactivate a respiratory phase.

Taking from the middle of the vessel serves to take an average of the formation activity that may be occurring at the bottom of top of the chamber and avoids any yeast trub that may have accumulated.

How Do You Calibrate and Use a pH Meter for Brewing?

Any new pH meters you buy will have already been calibrated. However, they lose accuracy when transported as well as over time. Generally, a calibration buffer solution will be supplied with the pH meter, or can be bought separately like these here on amazon.

Using the buffer solution

There are usually two buffer solutions, a 7 pH and 4 pH to which the pH meter will calibrate itself. In more sophisticated laboratory models, a 10 pH buffer solution may also be used.

Digital pH meters have a calibration button that you press when the probe is submerged in the buffer solution. Once it has had a moment to stabilize, you press the calibration button again and the meter will self-adjust to bring its reading in line with the buffer solution pH.

Some older style meters have a little screw on the pH meter which you must turn to correctly set the pH level

Read More: This article takes you through a step-by-step guide on how to calibrate your pH meter.

What is the Ideal pH for Fermentation?

As we have established, the pH scale is a measurement of the total acidity or alkalinity of a substance.

The scale measures from 0 to 14.0, with 7.0 being neutral. Any substance that has a pH of less than 7.0 is considered acidic. Any substance that has a pH of more than 7.0 is considered alkaline, or basic.

Yeast cells in fermentation can tolerate a pH of 4.0 to 8.5 but will work best when the pH is between 4.0 and 6.0. This means that the yeast cells require a slightly acidic environment to do their best fermenting.

- The pH for fruit fermentation should be kept 4.5 and 5 as a rule of thumb.

- With grain mashes, keep the pH between 4.8 and 5.2 (ideally around 5.0).

- The pH requirements can be confirmed based on the technical specifications of the yeast strain chosen. Read the datasheet!

| Alcohol | Recommended Fermentation pH |

|---|---|

| Beer Wort | Between 4.8 and 5.2 |

| Sour Beer Wort | Between 3.0 and 3.5 |

| Cider | Between 2.8 and 3.8 |

| Wine | Between 3.2 and 3.8 |

| Whiskey Wash | Between 4.8 and 5.5 |

| Vodka Wash | Between 5.0 and 5.5 |

Note: remember to also consider the ideal fermentation temperature of the yeast you are using.

What Happens if the pH is Too High or Too Low?

With either one, you are going to have fermentation that does not have a good conversion of sugar to alcohol.

If it is too high, you may expose your fermentation to a bacterial infection, most prevalent with wine.

If it is too low, however, there is a high chance of your fermentation stalling or lagging completely to zero activity.

What Is The Best Way To Make The pH Lower Or Higher?

So what happens if you pH is off? How can we fix it?

Firstly, in most cases you’ll be needing to LOWER the pH not increase it, so I wouldn’t really worry about buying anything to increase the pH unless you’re specifically fermenting sour fruits for example or sugar wash is also notorious for crashing the pH.

- To increase your pH, use a food-safe base like calcium carbonate, calcium hydroxide or crushed oyster shells.

- To decrease your pH level, use a weak food acid like lactic acid or citric acid.

These products will do the job correctly without affecting the flavor.

How To Raise The pH

1. Calcium Carbonate.

Calcium carbonate is a weak base that is commonly used to make water chemistry adjustments and also raise the pH. Use a few teaspoons in a 5gal batch and then re-check your pH reading.

Note: Calcium carbonate is not very soluble so some people have trouble getting it to disolve right away.

These will normally have some time lag between addition and effect. This means that it is easy to “overdose” the fermentation and end up with a pH that is either too high or too low.

2. Calcium Hydroxide.

Calcium Hydroxide is a stronger base and commonly used in commercial breweries. It’s more soluble that Calcium carbonate, but a little goes a long way so be careful not to overshoot! One teaspoon is usually enough for a 5gal batch.

3. Crushed Oyster Shells.

Crushed oyster shells will also raise the pH and have a great buffering effect. This is useful in sugar washes where there arent enough salts to buffer against pH changes during formation and as a result it can drop very quickly.

It can be bought from farming supply shops next to the chicken feed (to help the chooks boost their calcium).

Use about half a cup in a hop sock in the fermenter for a 5gal batch.

How To Lower The pH

1. Lactic Acid.

Lactic acid is my go-to souring agent. It’s food safe and relatively flavorless, unlike citric acid which creates more of a twang.

This can be bought from most homebrew shops as an 88% concentrate. Make sure to get a syringe or piptte at the same time to help with dosing.

A good rule of thumb is to use 0.25ml of lactic acid per 1kg of grain.

2. Citric Acid.

Readily available from the supermarket and is probably already in your pantry – I’ve used this many a time when in a pinch.

Some brewers can perceive the citrus twang when using too much so use sparingly.

3. Phosphoric Acid

This is probably the most popular acidifying agent used by commercial breweries since it has very little impact on flavor and contributes phosphate ions to the mash.

Use around 3ml of 10% phosphoric acid solution per 1kg of grains used.

Caution: This is also often sold as 85% concentrate solution. I’d stay away from this as any spills can cause burns and skin irritation so go for the 10% solution instead.

4. Calcium Sulfate

Another option if trying to add some calcium ions (good for the yeast!) to your brew is with calcium sulfate. start with one teaspoon be 5gal and increase if needed.

I am trying to raise a ph of 2.2 to above 4 in a 42# box of Key Line Puree from Oregon. I’m using Calcium Hydroxide and after adding a pound to about 25# it’s only raised the ph to 3.8. I’m concerned that there may be residual compounds (salt?) that will present fermentation if I continue adding more Calcium Hydroxide. Any suggestions?