Distilling, Distilling 101

Distillation Column Flooding (How To Prevent It)

Flooding is frustration – throwing your still out of equilibrium and often ruining your product..

But, the good news is that you can fix it mid-distillation or prevent it from happening in the future.

Flooding still is often a result of a higher than normal reflux rate. It could also mean there’s a high feed rate which prevents the vapors from condensing effectively so as to move through the column. Finally, if you’re running your still at very high temperatures, it does create turbulence which can result in a flooded still.

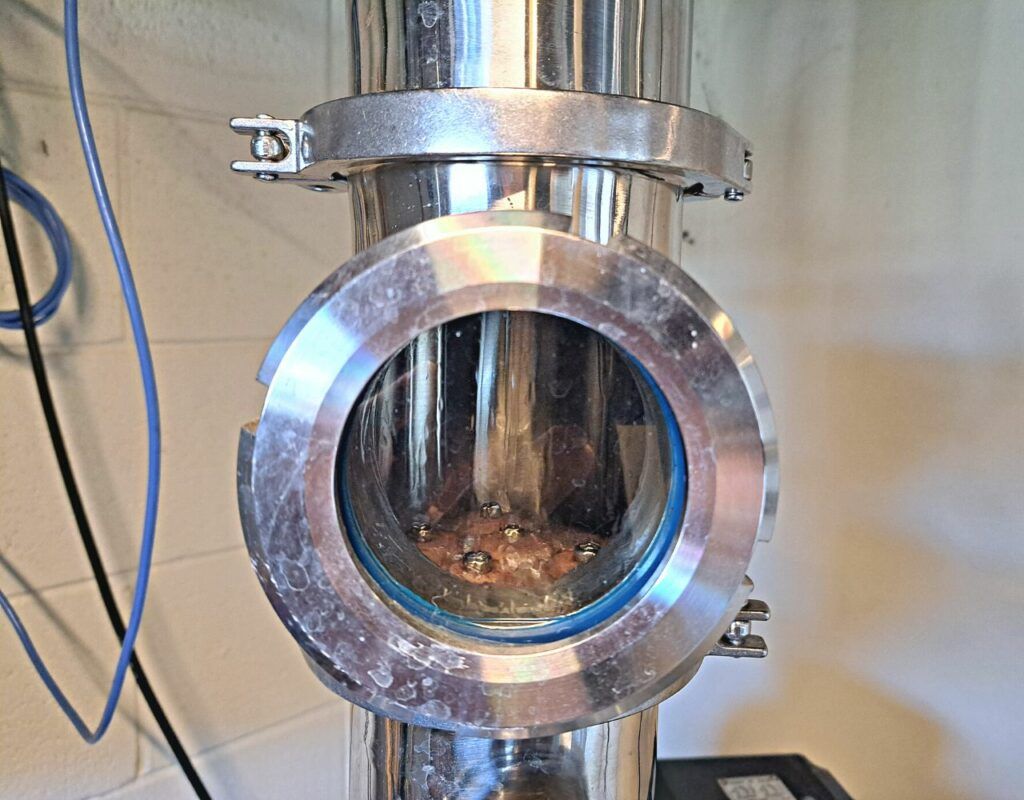

Ways to control a high reflux rate include reducing the feed rate to create enough head space for the liquid to cool and convert to vapors. Also, when you see the liquid build-up (when using a still with a sight glass) or when you hear bubbling inside the still (for stills without a sight glass), it means you need to control your heat.

In this post, we will dive deeper into the causes of a flooding column and how to prevent it.

Table of Contents

What Exactly Is Flooding And What Causes It?

Flooding is when there’s an excess liquid flow rate in the column. The main causes include:

- System pressure and excess feed rate. A study found that pressure restricts vapors from rising through the column, and the liquid builds up on the trays. If overloading continues, more and more fluid backs up and blocks vapor.

- Higher than regular reflux rate. Too much reflux results in heightened liquid levels in trays and increases the hydrostatic pressure of the liquid, thus restricting vapor flow.

- A low reflux temperature makes the vapors condense quicker, which does overload trays and blocks the flow of vapor.

- Too high a temperature increases the flow of vapor, resulting in an excess of liquefied vapors. Increased vapor flow forces liquid up the column which floods the trays.

- Damage to column packing and scale build-up. Scale buildup and defective internal components can restrict the flow of vapors and liquid. This will block the packing causing the still to flood sooner than it would normally

How To Tell If Your Distillation Column Has Flooded?

There are ways to identify if your still has flooded. The process is easier when you’re using a column with sight glasses because you can witness the overflow and turbulence, but it’s not always the case with one without sight glasses. However, this does not mean it’s undoable. Here’s how to tell if your distillation column has flooded.

With sight glasses

- The liquid boils rapidly and the compounding is visible as the flow gets blocked.

- The thermometer gets covered with liquid and makes the temperature reading off.

Without sight glasses

- The column will sound like it’s boiling inside the column.

- Liquid might exit the column as a way to equilibrate the reflux rate in the column.

How To Fix A Flooded Still

Now that your still has flooded, you might be wondering, does that mean you need to stop the distillation process entirely? Not really, you can put practices in place to ease the rapid reflux rate. Here’s how to fix a flooded still.

- Turn down the heat and allow the flooded column to drain.

- Readjust the heat and let the column cool down before it boils over.

- Turn off the heat completely so the column regulates the flow of vapors.

How To Avoid Flooding Your Still

Luckily for you, there are various steps to take to avoid flooding your still. Here are some tips on how to do that.

- Experiment with your still and adjust the temperature. This allows you to control the pressure within the still.

- Decrease the feed rate and reflux rate.

- Closely monitor the heat during the first run and adjust the temperature accordingly to reduce the flow rate of vapor up the column.

Conclusion

A flooded still, in essence, means you need to be aware of how your still runs. Though this can be challenging if you’re still new to using your equipment, the good news is you can control the reflux rate at mid-distillation.

You can do this by controlling the temperature of your still so the column can cool down a bit before any turbulence occurs. If you’re used to churning in a lot of feed, then that could also be the culprit. Though it can be time-consuming, regulating the feed rate prevents the likelihood of column flooding.

Once you’ve applied the tips in this post on preventing your still overflowing, this scenario will be a thing of the past.