Distilling Hardware, Tools and Equipment

What Is A Liquid Management Still? (And How Do They Work?)

There are many different reflux still topologies, each with their own benefits and drawbacks.

One of the designs that has gained popularity due to its simplicity is the Liquid Management Still or LM still.

A liquid management still controls the amount of liquid being drawn off the still. It uses internal plates below the dephlegmator/column condenser too collect the distillate being sent back down the columns and a take off port at the bottom plate. The reflux ratio is controlled by restricting the liquid being taken off and therefore forcing it to overflow back down the column.

In this post, we’ll discuss what is liquid management still and how it works, so you’ll know whether or not it’s worth the investment.

Table of Contents

What Is A Liquid Management Still?

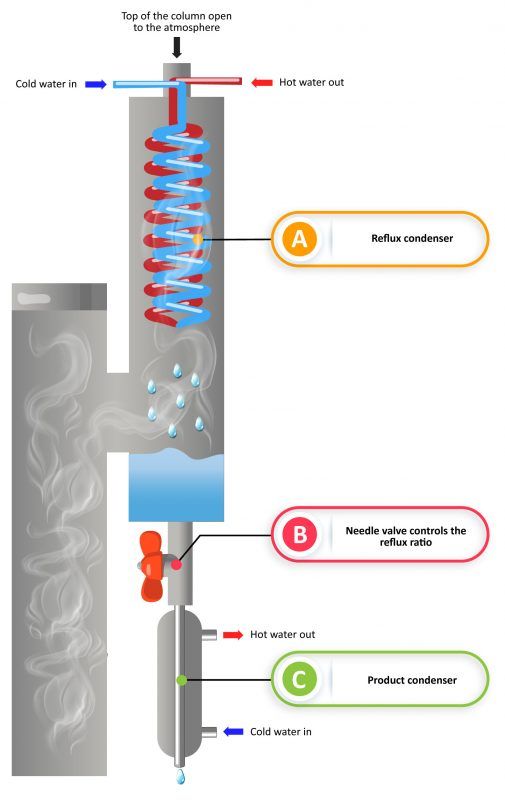

A liquid management (LM) still allows the distiller to control the amount of liquid exiting the condenser through a needle valve.

How Does A Liquid Management Still Work?

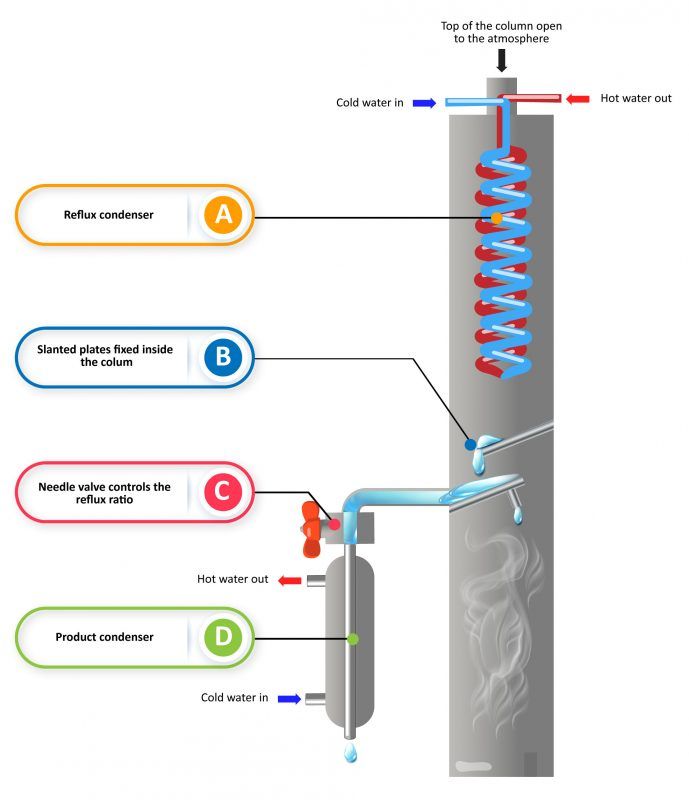

LM stills works by condensing vapors as they move through a column. Within the column, there are two copper plates/slants placed at an angle. Vapor reaches the condenser at the top of the column and condenses into a liquid. The liquid then drops onto the plates or down the column.

When the liquid has settled on the plates, the distiller opens the needle valve to allow the desired liquid to be collected. By keeping the valves closed, the distiller can let the reflux action proceed, up to a point where they can collect the pure alcohol (ethanol).

Advantages And Disadvantages Of A LM Still

Similar to most stills, the LM still does have its limitations. Here are the advantages and disadvantages of the still.

Advantages

- Precise control of heat and can hold back on impurities, like the tails.

- Can produce up to 96% ABV.

- Produces a pure spirit with a high alcohol by volume (up to 96% ABV /192 proof).

- Gives you control over your reflux ratio.

Disadvantages

- Not beginner friendly – you must have a good understanding of how to control the valve to restrain the liquid exit rate.

- The more you open the valve, the less the alcohol percentage.

- Pricey – expect to pay approximately $600.

Components Of A Liquid Management Still

LM stills are made of two components: the column and a head, and they are connected by a tri-clamp.

Parts of a column

The column is packed with a stainless steel or copper scrubber. It also has a ferrule inserted at the bottom with a lock nut to connect the column to your boiler. At the top, there’s another ferrule connecting the head to the column.

Parts of the head

- Plates: Used to collect the needed amount of liquid.

- Needle valve: Controls the distillate leaving the still.

- Needle valve outlet: An exit point for the distillate.

- Thermowell: To insert the thermometer.

- Copper condenser coil: Instantly cool vapors.

- Coolant tubes: Condenses the vapors.

- Copper slant: Used to transfer and hold liquid as it falls down the condenser.

Different Liquid Management Still Topologies And Designs

There are different designs of the LM still on the market, here are the most common ones.

Cooling tube design a.ka. forced reflux still

The forced reflux design has tubes inserted through the column through which water flows. They have direct contact with the rising vapors and instantly condense the vapors, forcing the liquid down the volume.

The continuous process of condensing takes place until the liquid at the lowest boiling point remains at the bottom of the column. To instantly cool the vapors, the distiller has to effectively control the speed and temperature of the water running through the tubes.

External valved design

The external valve design is the most popular design amongst home-distillers. Its design is such that the reflux takes place outside the column. Vapors travel through a fitting across the reflux, into a forcing reflux section packed with a cooling copper coil.

The coil instantly condenses vapors, then the liquid drops into a reservoir with a needle valve. The valve allows the distiller to control the speed at which they restrain the flow of the distillate while in turn controlling the liquid going back into the column.

Internal valve

Commonly known as the Bokakob “Boka”, this still has its valve connected to the forcing reflux. It works in a similar fashion as the external valve.

What Is A Liquid Management Still Good For Making?

Liquid management stills have a tall column which means there’s an increased surface area for the vapors to reflux and separate from alcohol. This results in purer, high-proof alcohol (95-96% ABV), so it’s good for making gin, vodka, or neutral spirits you intend to flavor when making liqueur.

Conclusion

A liquid management still is one of the best stills for home distillers who have mastered reflux control – ensuring a refined spirit with every run. Using liquid management still means you’ll have full control of making cuts because it effectively strips impurities due to the continuous reflux action.

And just because it strips off a lot of impurities, it doesn’t mean you’re limited to the spirit you can make. You can use the final product to prepare flavored liquors like apple moonshine or infuse botanicals for gin.