Distilling, Distilling 101

Why Is My Moonshine Low Proof (13 Reasons Why)

This article is written for anyone trying to distill at home, but aren’t getting the ABV (or proof) they are expecting.

I’ve been there before (many times) and understand just how frustrating it is.

We’ve broken it up into two main sections; pot stilling and reflux stilling as there are different factors at play for each scenario.

TLDR; We’ve found the 13 most common reasons for low-proof distillate are as follows;

- Low ABV of the wash

- Still is puking

- Running too long

- Need to distill twice

- Flow rate is too high

- The column isn’t in equilibrium

- Column is flooded

- The reflux ratio is wrong

- Quality of your distillation equipment

- The column is too short

- Not enough bubble plates

- or not enough packing material

- The wrong type of packing material.

Table of Contents

Why Is My Moonshine Low Proof (13 Reasons Why)

As someone who has tried to distill at home, you might have encountered the problem of not getting the expected alcohol by volume (ABV) in your moonshine. There are many factors that could contribute to this problem, and in this article, we will break down the most common reasons for low proof distillate. We will explore the different scenarios of pot stilling and reflux stilling, and give you tips on how to improve your distillation process.

Pot Still Distilling

1. Low ABV of the Wash

The wash, also known as the mash, is the mixture of water, sugar, and yeast that ferments to create alcohol. If the initial ABV of the wash is low, the final distillate will also have a low proof. To increase the ABV of your wash, you can add more sugar or use a different yeast strain that is more efficient at converting sugar to alcohol.

| Wash %ABVResulting ABV After Distilling in a Pot Still | |

|---|---|

| 5% | 35% |

| 10% | 53% |

| 15% | 62% |

| 20% | 67% |

| 25% | 71% |

| 30% | 73% |

| 35% | 75% |

| 40% | 77% |

| 45% | 78.5% |

| 50% | 80% |

2. Still is Puking

Puking is when the foam produced during distillation overflows and enters the condenser. This can happen if the still is filled with too much wash, or if the heat is too high. To prevent puking, make sure you don’t overfill your still, and control the heat output to maintain a steady boil.

Read more: We explain how to prevent puking in this article.

3. Running Too Long

Running your still for too long can also result in low-proof distillate. The longer the distillation process, the more water, and other impurities will be collected along with the alcohol. To avoid this, use a good quality alcoholmeter and proofing parrot to monitor the ABV of the distillate as it comes out of the still, and stop collecting once the ABV drops below a certain point (I stop at 25% on a pot still run).

Refer back to the table in point 1. As you get further into your run, the alcohol content in the boiler will drop, so, therefore, the product alcohol will also decrease. Easy!

4. Need to Distill Twice

If your initial distillate has a low proof, you can try distilling it a second time to increase the ABV. This process, called double distillation, involves using the initial distillate as the wash for a second distillation. The second distillate should have a higher proof than the first.

Typically, we call the first run a stripping run, and the resulting product are low wines. The low wines then go through a spirit run to get the final product.

Reflux Still Distilling

5. Flow Rate Too High

The flow rate of the wash and the cooling water can affect the reflux ratio, which in turn can affect the proof of the distillate. If the flow rate is too high, the reflux ratio will be too low, resulting in low proof distillate. To adjust the flow rate, use a flow meter to measure the rate of the wash and cooling water, and adjust as necessary.

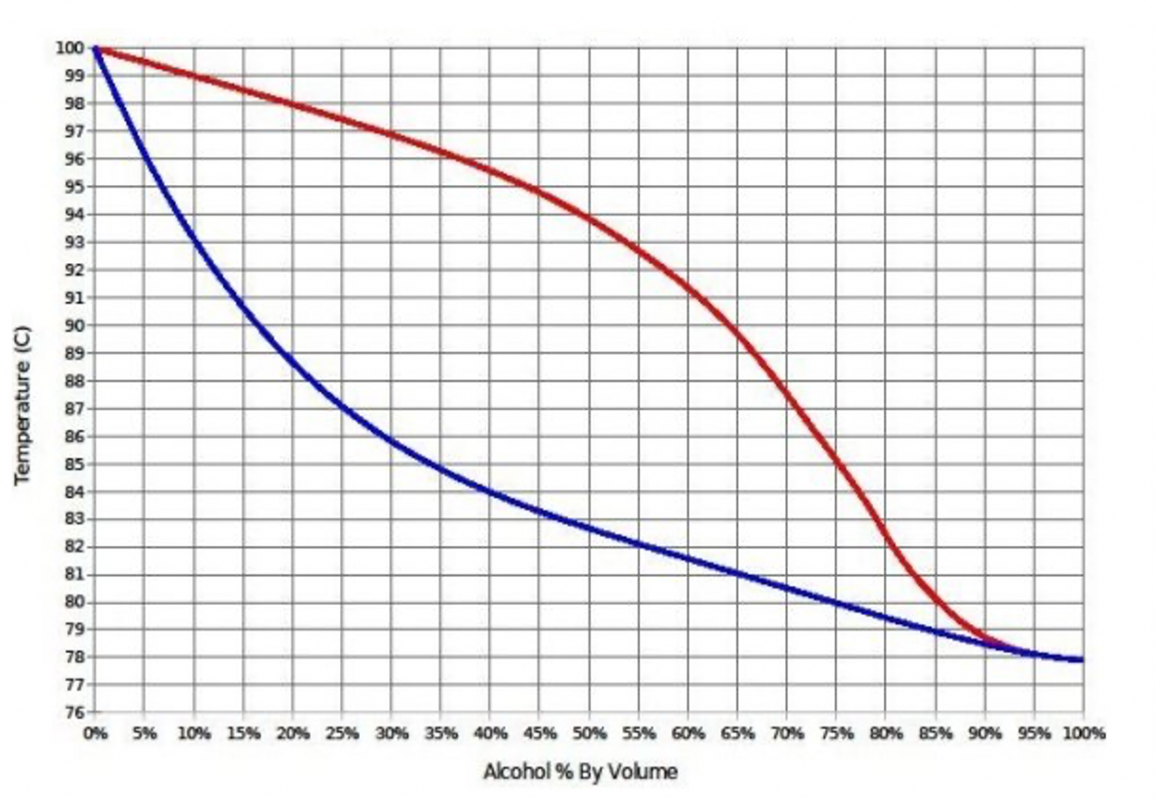

6. Column Isn’t in Equilibrium

In a reflux still, the column needs to be in equilibrium for the distillation process to work effectively. This means that the vapors rising up the column should be in balance with the liquid flowing down the column. If the column isn’t in equilibrium, the distillate will have a lower proof. To achieve equilibrium, adjust the cooling water flow rate and the heat output.

7. Column is Flooded

If the column is flooded, it means that the liquid flowing down the column has accumulated and is blocking the vapor flow. This can happen if the cooling water temperature is too low, or if the flow rate is too high. To prevent flooding, make sure the cooling water temperature is at the correct level, and adjust the flow rate as necessary.

8. Reflux Ratio is Wrong

The reflux ratio is the ratio of the amount of liquid that is returned to the column to the amount of liquid that is collected as distillate. If the reflux ratio is too low, the distillate will have a lower proof. To adjust the reflux ratio, increase the amount of liquid that is returned to the column, or decrease the amount of liquid that is collected as distillate.

Other Factors

9. Quality of Your Distillation Equipment

The quality of your distillation equipment can also affect the proof of your distillate. If your still is poorly constructed or made from low-quality materials, it can lead to leaks, poor heat distribution, and other issues that can result in low proof distillate. Invest in quality equipment to ensure consistent and high-quality distillate.

10. Column is Too Short

In a reflux still, the height of the column can also affect the proof of the distillate. If the column is too short, the distillate will have a lower proof. To increase the height of the column, you can add more packing material or bubble plates.

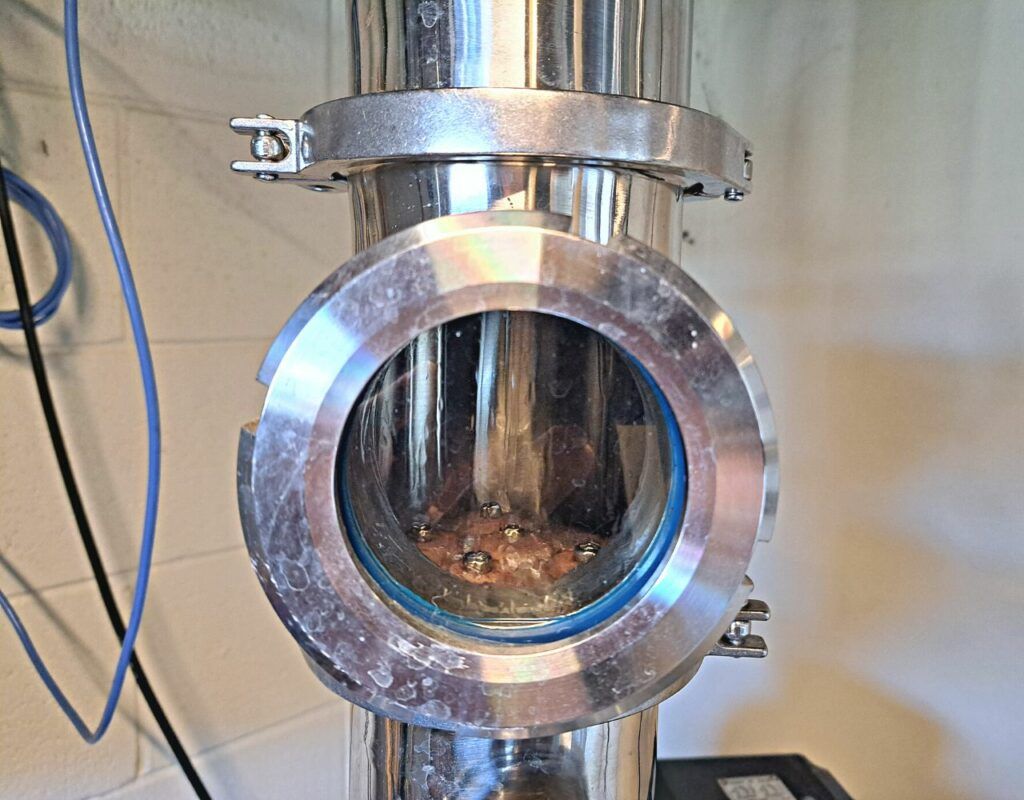

11. Not Enough Bubble Plates

Bubble plates are used in reflux stills to increase the amount of contact between the vapors and the liquid flowing down the column. If there aren’t enough bubble plates, the distillate will have a lower proof. To increase the number of bubble plates, you can add more plates to the column.

In general, a reflux still with 13-15 bubble plates can produce a neutral spirit with an ABV of around 94-95%. Keep in mind that the number of plates needed can vary based on the size of the still, the type of packing material used, and other factors.

12. Not Enough Packing Material

Packing material is used in a reflux still to increase the surface area of the liquid flowing down the column. If there isn’t enough packing material, the distillate will have a lower proof. To increase the amount of packing material, you can add more to the column.

HETP stands for “Height Equivalent to a Theoretical Plate”. It is a measure of the efficiency of the packing material in a distillation column. A lower HETP value indicates that the packing material is more efficient at separating the components of the distillate. Different types of packing material have different HETP values, and choosing the right packing material can help improve the proof of your distillate.

| Packing Material | HETP (cm) |

|---|---|

| Copper Mesh | 3.6 |

| Ceramic Raschig Rings | 5.0 |

| Glass Raschig Rings | 2.5 |

| Stainless Steel Scrubbers | 2.0 |

| Structured Packing | 1.0 |

13. Wrong Type of Packing Material

The type of packing material you use can also affect the proof of the distillate. Different types of packing material have different surface areas and densities, which can affect the reflux ratio and the final proof. Experiment with different types of packing material to find the one that works best for your still.

Based on the table above, structured packing has the lowest HETP value, indicating it is the most efficient at separating components in the distillate. Therefore, structured packing can help improve the proof of your distillate. One option for purchasing structured packing material is here.

My Final Thoughts

There are many factors that can contribute to low proof distillate, but by understanding these common issues, you can take steps to improve your distillation process. Whether you are using a pot still or a reflux still, make sure you are using quality equipment, monitoring the ABV of the distillate, and adjusting the flow rate, reflux ratio, and other factors as necessary. With practice and patience, you can create high-quality moonshine with the proof you desire.